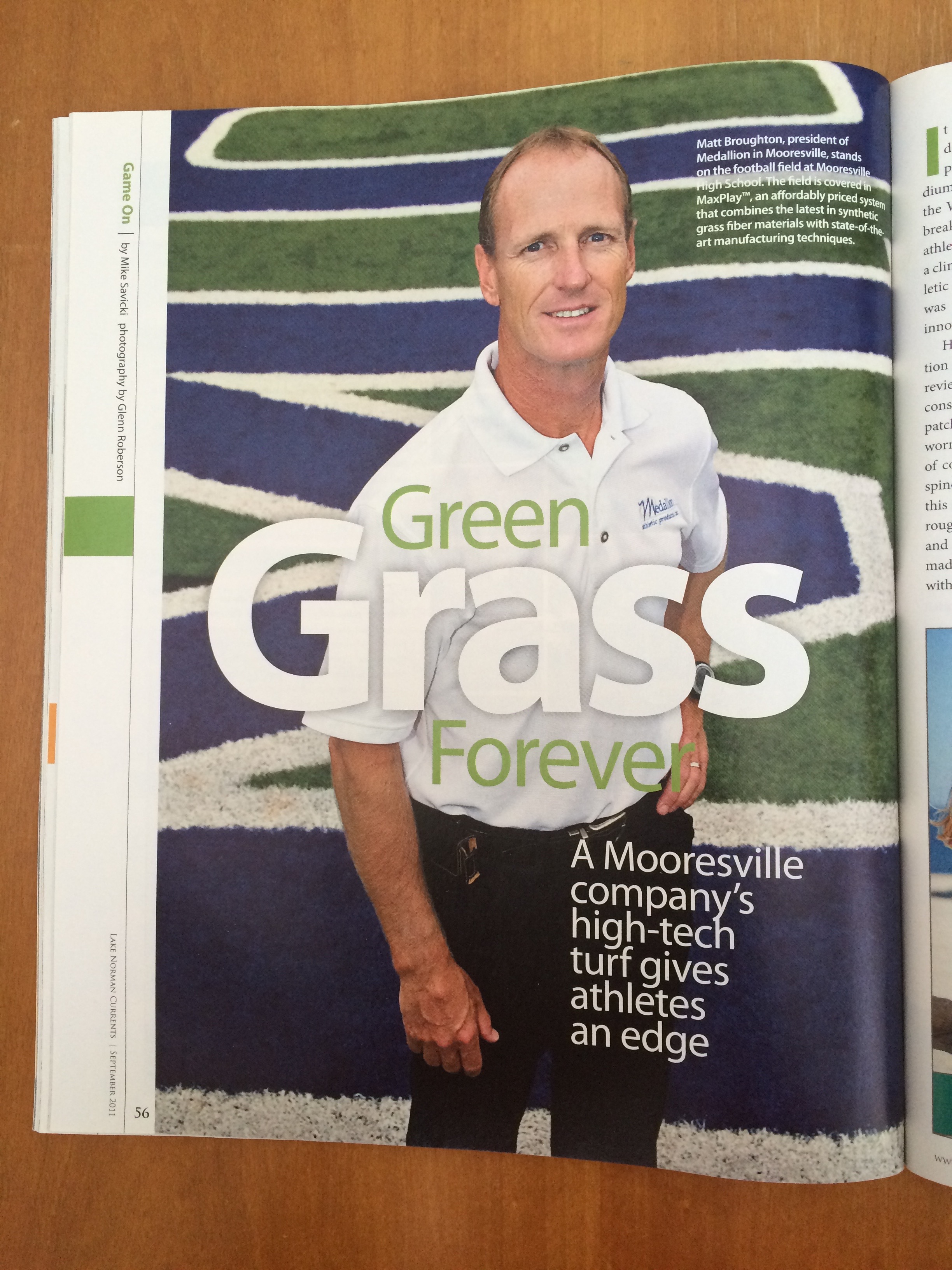

Green Grass Forever

A Mooresville company’s high-tech turf gives athletes an edge

By Mike Savicki

It was 1965 when the Houston Astrodome opened as the world’s first multi-purpose, large scale, domed sports stadium. Nicknamed the “Eighth Wonder of the World,” it featured numerous groundbreaking innovations that changed the way athletic events were played and viewed in a climate-controlled environment. The athletic surface it featured, called AstroTurf, was perhaps the most visible and lasting innovation.

However, the introduction of this new sports surface was met with mixed reviews by athletes. While the surface was clean and consistent and eliminated visible dirt patches and growth flaws, the very thought of competing on it sent shivers down the spines of competitors. Early generations of this artificial turf surface were uneven and rough on the body. Balls bounced higher and bodies fell harder. While the surface did make it possible to play more consistently without regard to weather conditions and deterioration, the surface quickly earned the reputation as being a poor substitute to natural grass.

“Original AstroTurf got a bad rap primarily because of its grip,” says Matt Broughton, President of Medallion Athletic Products in Mooresville. “The old-style surface was very hard because it was often rolled directly over concrete with little cushion. Athletes suffered more knee and ankle injuries than on natural surfaces. Abrasion was another issue. Basically, nobody liked to play on those surfaces if they had a choice.”

In 1996, Broughton founded Medallion Athletic Products to build and install indoor soccer boards for clients he had originally hoped would build ice hockey arenas across the south. As a Canadian who moved to help promote the game he grew up playing and coaching, Broughton felt a city like Charlotte could likely support at least one ice arena, and he wanted to be on the leading edge of what he thought would be a wild growth trend. The thought of being a full service turf contractor was not on his radar.

But the hockey explosion never materialized across the southeast, and Broughton refocused his business model. His new company diversified and began selling and installing artificial athletic surfaces, as well as a diverse line of other athletic products, including hardwood flooring, gymnastics products, protective netting, gymnasium dividers and batting cages.

For its first eight years, Medallion partnered with other brand suppliers of artificial turf products before branding its own turf product, MaxPlay™, in 2004. MaxPlay™ is an affordably priced system that combines the latest in synthetic grass fiber materials with state-of-the-art manufacturing materials. It is an innovative, high-quality, safe, low-maintenance playing field with maximum durability and sustainability.

According to Broughton, modern artificial surfaces are far more advanced and more closely replicate play on pristine natural surfaces. The product consists of the turf surface, the infill and the sub-base. The turf surface is composed of polyethylene plastic blades that simulate grass. The infill, which keeps the blades upright, can be composed of anything from recycled tires and athletic shoes to thermoplastic and silica sand.

Broughton believes that although the colorful turf is what most people see, no one component is more important than another. He explains, “We feel as though the base under the surface is as important, if not more so, than the turf itself. In the old days, you had a base contractor and you had a turf contractor. If there were issues during construction, there was finger pointing between parties. Our vision was to bring it all together under one roof so we controlled everything. We have our own base installers and turf installers and find we do it best ourselves.”

While the initial cost of installing an artificial playing surface is higher than the natural alternative, the low maintenance requirements, as well as higher opportunity cost related to increased playability, make it attractive to clients.

“On a natural surface, consistent, repeated play results in a breakdown of the surface, and that can stop play. On fields like ours, you can bring in as many teams as you like and play continuously without worrying about the surface conditions changing from the first game to the last. And over time, a surface like ours can break even in just a few years,” Broughton says.

Medallion’s focus is primarily on facilities in the southeastern United States, although it has completed projects from coast to coast. One of the company’s first projects was a 5-field, multi-use project for the City of Asheville. They have also completed regional projects at Clemson University, Winthrop University, South Carolina State and Eastern Carolina University, as well as Mooresville High School. Broughton and his team of 30 have now installed more artificial turf projects in the state than any other company. Their product has been annually recognized by the American Sports Builders Association for its construction excellence.

“I put a grade on every field I see, and I want people to be truly satisfied, not just with the surface itself, but with the entire process,” concludes Matt Broughton. “What motivates me is the quest for the perfect field. And when I say that, I mean all aspects of the project, like customer service and how our company did from the initial contact right through to our last employee leaving the job. As we know from history, the surface is what people see and athletes use, but, in my opinion, success is not just about the surface itself.”

This article was originally published in the September 2011 edition of Currents Magazine.